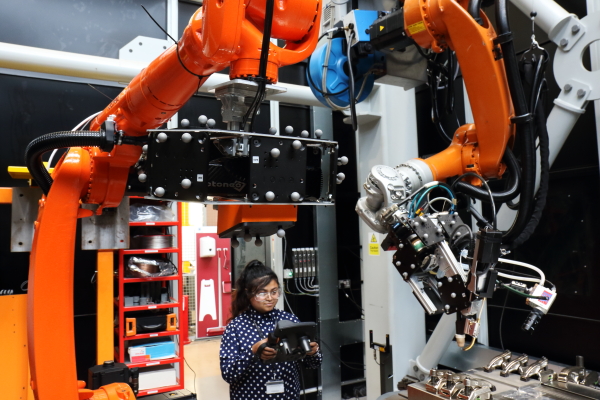

BMD Infrastructure Services joins Nuclear AMRC

BMD Infrastructure Services has joined the Nuclear AMRC to collaborate on technology development and expand its presence in the nuclear sector. A leading infrastructure advisory business which forms part of…